Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | JiangSu China |

| Brand Name: | JiaYuan |

| Certification: | CE, SGS |

| Model Number: | CGF18-18-6 |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 19450-19500 per set |

| Packaging Details: | This type of pure, mineral water filling machine would be wrapped up by plastic films. and covered up by extra padding like cartons and with lots of poly foams applied all around. and then put into a 2650*2000*2400 mm solid wooden case, Then the whole set |

| Delivery Time: | 30 days |

| Payment Terms: | Western Union, L/C, T/T |

| Supply Ability: | 10 sets per month |

| After Sale Service: | Engineers Available To Service Machinery Overseas | Dimension: | 2450*1800*2200mm |

|---|---|---|---|

| Certificates: | CE, SGS | Weight: | 3500kg |

| Brand: | JiaYuan | Power: | 5kw |

| Voltage: | 220/380V | Model Number: | CGF18-18-6 |

| Driven Type: | Electric | Automatic Grade: | Automatic |

| Application: | Beverage | Packaging Material: | Plastic |

| Packaging Type: | Bottles | Capacity(500ml): | 5000BPH |

| Filling Material: | Pure/Mineral Water | Bottle Type: | PET/Plastic Bottle |

| Bottle Volume: | 300ml-2500ml | Cap Type: | Plastic Screw Cap |

| Warranty: | One Year | Machine Control: | Siemens/Mitsubishi PLC System |

| Filling Precision: | Within ±5 Mm Of Error Of Liquid Level | Filling Method: | Sterilizing/Rinsing/Filling/Capping In One Machine |

| Air Consumption: | 0.6 M3/min | ||

| High Light: | liquid bottle filling machine,water bottling machine |

||

1. Briefs on product

a. This type of water filling machine is for the pure/mineral water production line. mineral water filling machine

b. Compact configuration along with rotary system make it samll in size but robust in production.

c. The outside frame is welded by 304 Stainless Steel, Key parts that contact the bottles directly are made by 316 Stainless Steel which is finely preprocessed.mineral water filling machine price

d. All of the electric components are made by the elite companies like Siemens, Mitsubishi, Omron, etc(customizable).

e. This type of water filling machine fills PET/plastic bottles. Its capacity reaches 5000BPH.

f. Filler's nozzle stroke is adjustable through a certain range, which means This filler can fill bottles with different volume(160ml-2500ml).

g. Photoelectric sensor installed inside the machine can detect if there are bottles coming, making sure no bottle no fill, no bottle no cap.

2. How does this pure, mineral water filling machine work:

a. Bottles are sent into the machine through air conveyor and all working parts of the machine start to rotate.

b. Starwheel inside the machine picks bottles up and sends them to the rinser. The rinser starts to wash the bottles.

c. The filler will get to work while rinser's done, The transportation is also conducted by a starwheel.

d. And then bottles will be sent to the capper by a starwheel, and capper starts to work.

e. At last, those filled and capped bottles will be sent out of the machine to the next stop.

air conveyor: installed between the bottle unscrambler and the 3-in-1 monoblock, send bottles into the machine from the unscrambler.mineral water filling machine price

starwheel: transport bottles mainly inside the machine and get bottles in the right position accurately before sending bottles to the rinser, the filler and the capper.

cap conveyor: transport the caps and feed them to the capper.

|

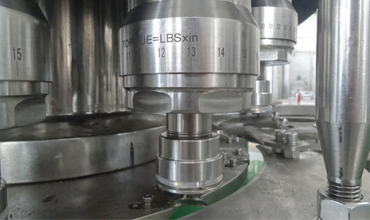

the rinser's clutches:

pick up bottles by clipping their necks and gradually turn them upside down while rotating. They will send bottles into rinsing area where bottles get washed by water thoroughly. |

|

the filler's nozzles:

They are made of finely preprocessed 316 stainless steel, The oval bulge that is right above each nozzle adjusts bottles into the right position before nozzles fill them up. The nozzle stroke can be adjusted to different bottles' volume. This whole combination just achieves highly accurate filling process. |

|

|

heads of the capper: mineral water filling machine price The capping module is highly accurate. With the help of the photoelectic sensor, the capper can do the capping motion based on the signal sent in by the photoelectric sensor. No bottle no capping. The caps are fed by the cap conyeyor normally placed outside the machine. |

3. Quality Assurance

4. Company Info

Company Information:

We locate in ZhangJiaGang, a small city near ShangHai. We have been focusing on the improvement of machinery theory and performance in beverage machinery. we have several certificates such as CE,SGS,etc. we have a batch of decent manufacturing facilities, a bunch professional staff, a string of diligent and farsighted leadship. Our machines are widely sold domestically and abroad. We've been majoring in complete beverage production line, including pure/mineral water production line, non-carbonated drinks production line, carbonated drinks production line.

5. Packaging and Shipping

6. Our Service

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler