Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | CHINA,MAINLAND |

| Brand Name: | jiayuan |

| Certification: | CE,SGS |

| Model Number: | RCGF |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 16000 -55000 set |

| Packaging Details: | wooden case |

| Delivery Time: | 15 work days |

| Payment Terms: | T/T |

| Supply Ability: | 15 sets per month |

| Color: | Silvery White | Certification: | CE,SGS |

|---|---|---|---|

| Product Capacity: | 3000bph | Water Consumption: | 800kg/h |

| Power: | 5.88kw | Weight: | 2500kg |

| Service: | Oversea Service | Voltage: | Customized |

| Highlight: | juice bottling equipment,pet bottle filling line |

||

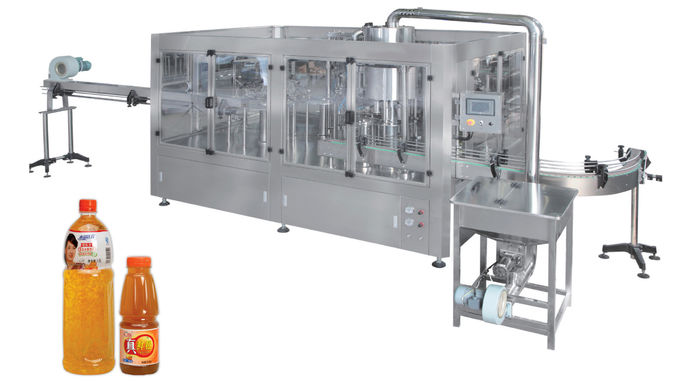

Juice Filling Machine 2100*1500*2200 SUS304 , Juice Bottling Equipment

Application:

This hot filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling, and capping, It is equipped with perfect temperature control system, reverse-flow system, automatic cleaning system and control program. Each machine element that contacts with the liquid is made of high quality stainless steel and food-grade rubber.

Parameter

| Model | RCGF16-12-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 |

| Production capacity(500ml)(b/h) | 3000 | 6000 | 10000 | 14000 |

| Filling precision | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) | ≤±5MM(Liquid Level) |

| Feedback consumption | ≤10% | ≤10% | ≤10% | ≤10% |

| Polyester bottle standard(mm) | (BottleDiameter)50-92;(Height):150-310 | (BottleDiameter)50-92;(Height):150-310 | (BottleDiameter)50-92;(Height):150-310 | BottleDiameter)50-92;(Height):150-310 |

| Suitable cap shape | (Plastic Screw Cap) | (Plastic Screw Cap) | (Plastic Screw Cap) | (Plastic Screw Cap) |

| Water pressure of washing bottle(Mpa) | 0.18 | 0.18 | 0.18 | 0.18 |

| Wash pressure of washing bottle(kg/h) | 800 | 1600 | 2500 | 3500 |

| Gas sourse pressure(Mpa) | 0.6 | 0.6 | 0.6 | 0.6 |

| Gas consumption(m3/min | / | 0.3 | 0.4 | 0.5 |

| Total power | 5.88 | 6.68 | 7.68 | 9.18 |

| Total weight | 2500 | 3000 | 4000 | 5000 |

| Dimensions(L*W*H)(mm) | 2100×1500×2200 | 2450×1800×2200 | 2750×2180×2200 | 3600×2800×3150 |

Description

The equipment is used for the production of wine, alcohol drink,mineral water, pure water, juice, etc.

It integrates washing ,filling ,capping together.The design is scientific and reasonable ,It's oppearance is beautiful ,operation and maintentic is convenient.

Washing part

a) Rotary pan is made of stainless steel 304.

b) The rubber clamp splice seizes the mouth of bottles, which is fixedness and reliable.

Filling part

a) Rotary pan is made of stainless steel 304

b) The way of filling is gravitation filling.

c) The filling valve is adopted best stainless steel 304

d) The structure of filling valve is reasonable, the amount is correct

e) When filling the bottle, the bottle is move but the valve is stationary. The splint of bottle-neck seizes mouth of bottles. The elevator device with the action of gear realize the up and down of bottle

Capping part

Capping machine is one of the highest precision machines, which greatly affects the reliability of device and the defective rate of product. The characteristic is as follows:

a) The dropping cap guide track fixes the device which can protect the cap from turning over and also set the device which can take out the inverse cap, equip a photo electricity switch which can

stop the machine when lacking the cap and also avoid the situation that there is bottle without cap.

b) The bottle inlet switch which is set in the capping machine, with the locking cap which is the connection of the dripping cap guide track and dialing cap pan controls the discharging of cap, making sure that stop conveyor cap when there is no bottles ,avoid the waste of cap.

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler