Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | CHINA,MAINLAND |

| Brand Name: | jiayuan |

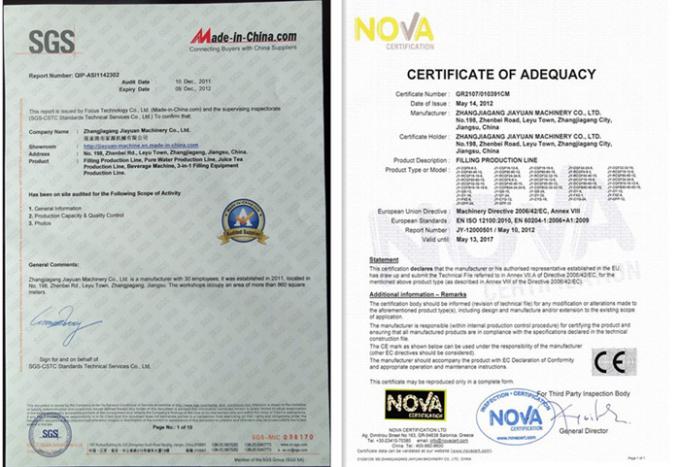

| Certification: | CE,SGS |

| Model Number: | CGF |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD 12000-65000 SET |

| Packaging Details: | wooden case |

| Delivery Time: | 30work days |

| Payment Terms: | T/T |

| Supply Ability: | 15 sets per month |

| Material: | Food Grade SUS304 | Voltage: | Customized |

|---|---|---|---|

| Service: | Oversea Service | Filling Type: | Normal Pressure Filling |

| Application: | Food, Beverage | Control System: | PCL Control |

| Certification: | CE,SGS | Name: | Filling Machine |

| Highlight: | liquid bottle filling machine,water bottling machine |

||

SUS304 8.63 KW Water Bottle Filling Machine , Water Pouch Filling Machine

Introduction

JIAYUAN CGF series mineral water filling machine and packaging machinery is a self-developed new product by our R&D department to meet the requirement of multi-usage demands for our customers. The mineral water filling machine is consisted of ringsing-filling-caping all together. It can fill mineral water, pure water and distill water etc. JIAYUAN CGF mineral water filling machine adpots the suspension design. It allows the machine to fill different type of the bottles. It is normally used as mineral water filling machine. However, it can also be used for fill PET bottle with fruit juice and tea at high temperature by simply change tha valve. It can be connected with our others machines to form the mineral water filling production line.

Application

This water filling machine is used in the production of non-carbonated drink, such as mineral water and purified water, etc.

1. The suspending bottle-neck clamping design make the bottle stable during the high speed moving conditions. By changing a few parts, it can meet the need of different types of bottles easily.

2. The new generation of stainless steel grab is adopted and the grabs have no contact with the arew above the bottle's screw thread. Nozzles in the grab can guarantee the complete wash of the interior of the bottle.

3. The advanced gravity filling technology used in this machine makes the filler quick,steady and accurate.

4. Magnetic torque is used for screw capping,and the power of screw capping can be adjusted steplessly. Capping is reliable and do no harm to the caps.

5. Advanced technologies,such as human-machine interface touch-screen and PLC program control are adopted in this machine.

6. All parts that directly contacting with water are made of high stainless steel. The critical electrical components are from famous international companies, such as mitsubishi, omron and other famous brands.

Technical Parameter

| CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | |

| Productivity | 2000-4000 BPH | 4000-6000 BPH | 8000-10000 BPH | 12000-15000 BPH | 16000-18000 BPH |

| Rinsing Head | 16 | 18 | 24 | 32 | 40 |

| Liquid Filling Head | 12 | 18 | 24 | 32 | 40 |

| Capping Head | 6 | 6 | 8 | 10 | 12 |

| Bottle Volume | 350ml~2000ml±10ml | 350ml~2000ml±10ml | 350ml~2000ml±10ml | 350ml~2000ml±10ml | 350ml~2000ml±10ml |

| Bottle Diameter | φ50-90 mm | φ50-90 mm | φ50-90 mm | φ50-90 mm | φ50-90 mm |

| Bottle Height | 150-310 mm | 150-310 mm | 150-310 mm | 150-310 mm | 150-310 mm |

| Filling Tolerance | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cap Size | 28mm and 30mm PE Standard Caps | 28mm and 30mm PE Standard Caps | 28mm and 30mm PE Standard Caps | 28mm and 30mm PE Standard Caps | 28mm and 30mm PE Standard Caps |

| Air Pressure | 0.5 MPa | 0.5 MPa | 0.5 MPa | 0.5 MPa | 0.6 MPa |

| Air Consumption | 500 L/min | 500 L/min | 500 L/min | 500 L/min | 500 L/min |

| Filling Water Consumption | 1.5 m3/h | 3 m3/h | 6 m3/h | 7.5 m3/h | 9 m3/h |

| Rinsing Water Consumption | 0.5 m3/h | 1 m3/h | 2 m3/h | 2.5 m3/h | 3 m3/h |

| Motor Power | 3.5kW | 3.5kW | 4kW | 7.5kW | 7.5kW |

| Voltage | 380V | 380V | 380V | 380V | 380V |

| Dimension | (L×W×H) 2640×1520×2340mm | (L×W×H) 2816×1883×2340mm | (L×W×H) 3194×2054×2560mm | (L×W×H) 3937×2846×2560mm | (L×W×H) 4940×3755×3200mm |

| Weight | 2500kg | 3000kg | 5300kg | 8000kg | 12000kg |

| Filling Principle | Gravity Filling | Gravity Filling | Gravity Filling | Gravity Filling | Gravity Filling |

Rinsing part

1) The rotary wheel is a fully AISI304 stainless steel welded structure.

2) The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of AISI304 stainless steel, this bottle clamp is hygienic and durable.

3) The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water

4) Covering of bottle clamps and elevator are product of IGUS

5) The rinse is driven by driving system positioned inside machine frame via gear transmission

Filling part

1) The filler is designed and manufactured with application of Italy technology, providing

hardware guarantee for securing product quality and reducing loss.

2) Rotary wheel are fully made of stainless steel AISI304.

3) Filling valves are designed and manufactured with German technology, made of AISI316L, featuring high filling accuracy and high filling speed.

4) Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder.

5) All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free

bearing.

6) Hydraulic pump is float-ball controlled.

7) The filler is driven by driving system positioned inside machine frame via gear transmission.

Capping part

1) The capper is most precise part in 3 in 1 filling machine, because the quality of machine ism important to running credibility and product quality.

2) The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

3) It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

4) Highly effective acentric way for cap sorting to reduce the abrasion.

Features of bottle filling machine/line/equipments:

(1) This series beverage filling line,packaging line,production line production line collected washing, filling, capping, labeling and packing machines together.

(2) it is suitable for kinds of beverage production, like juice, tea production, simultaneously only change some spare part, then it can be used in the pure water, mineral water production line.

(3)adopts advanced normal pressure gravity for filling, the filling effect are fast, steady, quasi and equipped with the material recirculating system, realize back flow independently, not contract with material and avoiding second pollution and oxidation.

(4)This equipment can satisfy with filing request of lower than 95 hot filling, filling valves and pipes material are according to sanitation standard, at the same time.

(5)The CIP self-cleaning interface there is RO water rinsing device before capping ensure bottle mouth is clean. We adopt magnetic torque capping head.

(6)Labeling machine is designed by our self with stainless steel frame.

(7)Hot shrink packing machine adopted original imported parts from Germany, Japan. It is easy to adjust for different size of bottle and package.

(8)The whole beverage filling line adopts human-machine interface, touch-screen, PLC computer controller and other advanced technologies. With automatic inspect system of filing temperature automatic, caps supplying material, high-temperature alarm, low-temperature shutdown and automatic return, no bottle, no filling, wait when lack of bottle, lacking caps shutdown and so on, realize no bottle, no filling.

Certification

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler