Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | Jiangsu, China (Mainland) |

| Brand Name: | JIAYUAN |

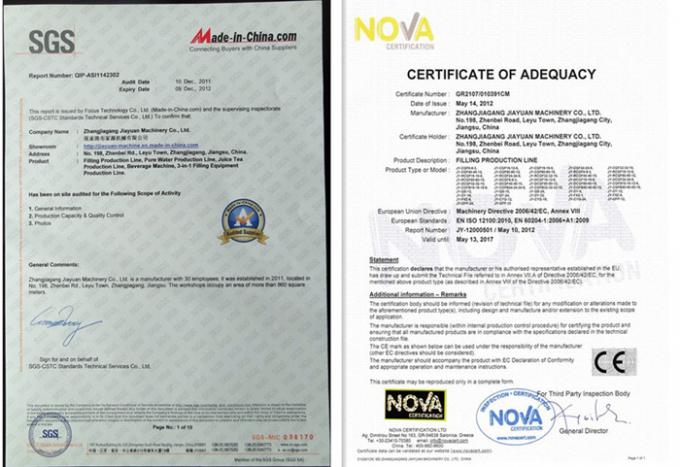

| Certification: | CE,ISO,SGS |

| Model Number: | DGCF16-12-6 |

| Minimum Order Quantity: | 1piece |

|---|---|

| Price: | US $30,000 - 560,000 / Set |

| Packaging Details: | wooden box |

| Delivery Time: | 30 working days |

| Supply Ability: | 10 Set/Sets per Month |

| Material: | Food Grade Stainless Steel 304 | Automatic Grade: | Automatic |

|---|---|---|---|

| Driven Type: | Electric | Voltage: | 380V 50HZ |

| Dimension(L*W*H): | 2750*2180*2200mm | After-sales Service Provided: | Overseas Service Center Available |

| Warranty: | One Year | Control System: | PLC Control |

| Filling Type: | Balanced Pressure Filling | ||

| High Light: | SS304 Sparking Water Production Line,PLC Sparking Water Production Line,2000BPH Sparking water filling machine |

||

1. It is used in the washing, filling and capping three function in a body,. The filling and seaming are designed in one body. The power of filling system is provide by the seaming system to assure the synchronization and harmony.

2. It is the latest equipment made on the basis of advanced technology of carbonated beverage drink filling line .

3. Adopt the advanced mechanism, electronic components and pneumatic control technology, apply isobaric pressure filling theory, the filling speed is fast, the liquid level is stable with loss. Seaming quality is good, the machine run smoothly, appearance is beautiful, operation and maintenance is convenient, the production speed apply frequency conversion, and long-distance control system can be collocated according to the request of client.

4. As the can is easy to get deformed, soft treatment is needed in the transferring process. The conveying system regulates the transferring speed according to the each machine’s working condition to assure no bottle falling or crashing occurs.

Features:

1.Multiple Usage: The filler provide a comprehensive range of different bottle sizes (height 150-320mm, Dia. 50-100mm)

2.Easy adjustment: An automatic height adjust device is available which offers you very easy operation only by pressing a button. For filling different size of bottles, relative parts can be easily and quickly changed without tools.

3.Advanced construction features: The filler carousel is mounted on a huge heavy duty combined bearing, which guarantees optimum smooth running of the filling bowl. The centering bell assemblies precisely locate the necks of bottles onto filling valves. The design of suspended and cantilevered bottle lift cylinders and bottle platforms allows easy, unrestricted remove of broken glass following bottle explosion which, with the addition of well protective of piston rods, minimizes the risk of damage of sliding surface of cylinders.

4.Sanitation: All parts which contact with beverage are made with high quality polished stainless steel. The CIP system offers automatically cleaning and sterilization of the filler.

5.Using PLC control the machine monitors, the filling liquid level automatically. Made up of high quality stainless steel, it is sanitation. Operation and maintenance is convenient.

Technique parameter:

| Model: | DGCF16-12-6 |

| Capacity :500ml | 2000BPH |

| Bottle shape: | round or square |

| Glass bottle: (mm) | (Bottle Diameter):φ50-.φ110mm (Height):150-340mm |

| Cap: | Crown cap |

| Filling precision: | ≤±5mm |

| Filling pressure:(Mpa) | 0.15-0.35 |

| Rinsing pressure:(Mpa) | 0.2-0.25 |

| Filling volume :(L) | 3.5 |

| Overall size:(mm) | 2450*1800*2200 |

| Weight: (kg) | 3000 |

Main Accessories

| Name | Supplier |

| PLC | SIEMENS |

| Touch Screen | SIEMENS |

| Transducer | SIEMENS |

| Air Switch,Circuit Breaker,Contacts | SCHNEIDER |

| Photoelectric Switch | SCHNEIDER |

| Proximity Switch | SCHNEIDER |

| Intermediate Relay | SCHNEIDER |

Please contact me and let's talk more details, thanks in advance!

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler