Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | China (mainland) |

| Brand Name: | JIAYUAN |

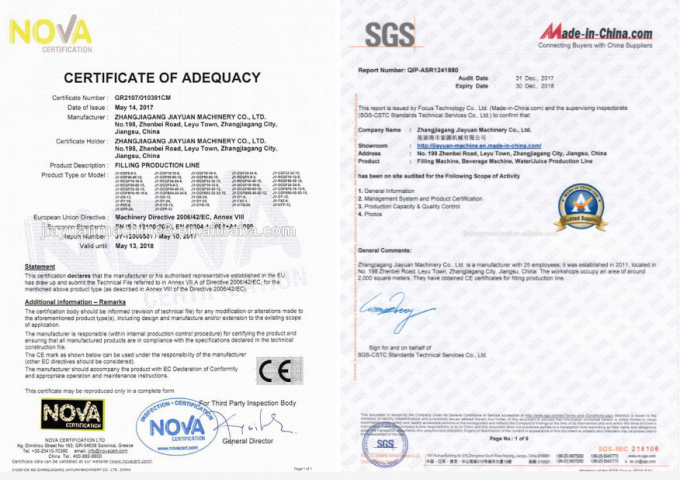

| Certification: | CE SGS |

| Model Number: | DCGF |

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD5000 per set |

| Packaging Details: | standard wooden cases |

| Delivery Time: | 35 working days |

| Supply Ability: | 100sets per year |

| Name: | Carbonated Drink Bottling Machine | Function: | Bottle Washing Filling Capping |

|---|---|---|---|

| Suitable Bottle: | PET Bottle | Bottle Volume: | 330-2000ml |

| Filling Material: | Carbonated Drink, Sparking Water, Soda Water ... | Capacity: | 2000-24000BPH |

| Material: | SUS304 | Warranty: | 1 Year |

| Highlight: | Carbonated Soft Drink Filling Machine,CSD Filling Machine |

||

Carbonated beverage rising filling capping 3 in 1 machine

Features:

1. This DCGF Wash-filling-capping 3-in-1unit:

2. Beverage Machinery is used to produce Gas beverage (CSD)

3. The DCGF Wash-filling-capping 3-in-1unit:Beverage Machinery can finish all the process such as press bottle, filling and sealing,

4. it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

characteristics:

1). Compact structured, good-looking, easy to operate and highly automated.

2). Air conveyor is directly linked with feed-in starwheels, making it easier to change bottles without screws and conveyor chains.

3). Bottles are transferred in the manner of clamping neck. Bottles can be changed through some replacement of steel clamps, which instead of adjusting the height of machine.

4). Rinser-clamp which special design is strong and endurable, no contact with bottle-mouth, to prevent pollution.

5). Highly effective spraying nozzles equipped on the rinser-clamp can rinse every side of inner bottle and save water.

6). Accessories which contact with material are all made of stainless steel, no dead angles and easy to clean up.

7). Replacement between CO2 and O2 ensure almost no O2 in bottle, long filling pipe reduce O2 content to null

8). Valve on-off system is driven by hydraulic cylinder, which starts on bottle signals.

9). High-speed and highly accurate bottling valves ensure no loss of liquid at high speed.

10). Equipped with CIP clean-in-place.

Technical parameter

| odel |

DCGF 16-12-6 |

DCGF 18-18-6 |

DCGF 24-24-8 |

DCGF 32-32-10 |

DCGF 40-40-12 |

DCGF 50-50-15 |

| Washing No | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling No | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Production Capacity(500ml) | 3000BPH | 5000BPH | 8000BPH |

12000 BPH |

15000 BPH |

18000 BPH |

| Install Capacity(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall size | 2450×1800×2400 | 2650×1900×2400 | 2900×2100×2400 | 4100×2400×2400 | 4550×2650×2400 |

5450×3210×2400 |

Machine pictures

inner look

About Rinser Station

Neck Control with plastic snap on the gripper.

Water distributor combined with Food Grade Rubber plate & SUS304 cover.

SUS304 water collecting tray

Spraying inject design, can completely washing the bottles.

Washed water recycling system, for water saving !! (Washed bottle---drip in water tank--water pump---raw water tank)

About Filler Station

The entire filler is isobar filling system.

High accurate SUS304L construction filling nozzle, make sure high accurate filling level

SUS304L liquid bowl, & pipeline system.

No bottles, no filling

Annulus Liquid bowl, with automatic water level controller

About the Capper

Place & capping system. Automatic caps arranging, feeding.

Electromagnetic capping heads, with burden discharge function,

All 304stainless steel construction

No bottle no caps delivery.

Automatic stop when lack of bottle.

electrical system

final products

about our company

our main production lines:

1. bottling minereal/pure water production line;

2. barrel mineral/ pure water production line

3. bottling carbonated beverage production line (like coca cola);

4. bottling juice production line;

5. canning beverage production line;

6. glass bottle beer production line;

7. milk/tea filling&package line;

8. oil filling&package line;

our two workshops

certificate

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler