Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | CHINA, jiangsu |

| Brand Name: | JIAYUAN |

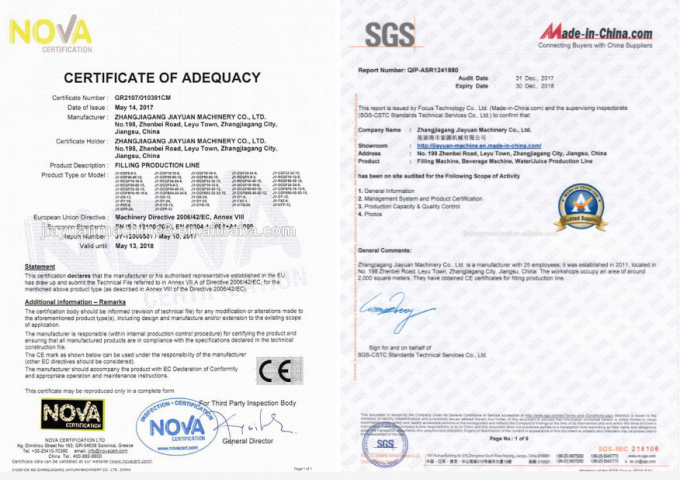

| Certification: | CE, SGS |

| Model Number: | CGF |

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 4000-40000 per set |

| Packaging Details: | standard wooden cases |

| Delivery Time: | 35 working days |

| Supply Ability: | 100 set per year |

| Name: | Water Bottling Machine | Function: | Rising Filling Capping |

|---|---|---|---|

| Suibtable Bottle: | 330-2000ml PET Bottle | Filling Material: | Mineral Water, Pure Water |

| Capacity: | 2000-30000BPH | Control: | PLC+Touch Screen |

| Warranty: | 1 Year | ||

| Highlight: | liquid bottle filling machine,water bottling equipment |

||

CGF series Non-carbonated Water Bottle 3 in 1 Filling Machines apply to the production of mineral water, purified water, flavor water and low alcoholic drinks, etc.

1. The machine concept of the CGF series was specifically designed for bottling in a hygienic environment;

2. Thanks to the free-standing transfer starwheels, there are much less exterior surfaces on the fillers than on conventional systems;

3. This innovative design has also the effect of the machine being very easily accessible for maintenance purposes and that it can be expanded at any time without conversion, for example with an additional cap feeder;

4. The OMRON PLC system offers the ideal solution for conductive non-carbonated fill products, as the fill quantity is measured precisely by an inductive flow meter;

5. All filling process steps can be programmed easily and individually – adjusted to the product to be filled and to the container.

6. With all variants of the CGF series for non-carbonated products, the containers are conveyed through the machine by means of neck-handling. This, as well as fill quantity determination via inductive flow meter (IDM) guarantee high flexibility and short change-over times;

7. Depending on the pitch circle, a central or a tubular ring bowl is employed;

8. Product feed pipes connect the product tank with the filling valves. In each connecting pipe, there is an inductive flow meter which measures the quantity of the product flowing through the pipes via the product’s conductivity;

9. The filling process begins after centring of the container and is effected by the free-jet method;

10. In order to be able to cope with the different bottles and products to be filled, one or two filling speeds are available.Non-carbonated beverages are filled pressureless in multi-chamber operation;

11. Once the preprogrammed amount of liquid has flown into the container, a flow meter signal will trigger closing of the valve;

12. The fill parameters and programmes are stored in the controller making quick change-overs via touch-screen.

Parameter

| Model | CGF12125 | CGF18186 | CGF24248 | CGF323210 | CGF404012 | CGF505012 | CGF606015 | CGF808020 |

| Number of washing, filling and capping heads | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 | 80-80-20 |

| Production capacity(600ml) (B/H) |

2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 | 25000-30000 | 35000-40000 |

| suitable bottle specification(mm) | φ=50-110=170 330-2250ml | |||||||

| Washing pressure(kg/cm 2 ) | 2-3 | |||||||

| Motor power(kw) | Main motor 2.2kw |

Main motor 2.2kw |

Main motor 3kw |

Main motor 5.5kw |

Main motor 7.5kw |

Main motor 11kw |

Main motor 15kw |

Main motor 19kw |

| Overall dimensions (mm) | 2400×1650 ×2500 |

2600×1920 ×2550 |

3100×2300 ×2800 |

3800×2800 ×2900 |

4600×2800 ×2900 |

5450×3300 ×2900 |

6500×4500 ×2900 |

76800×66400 ×2850 |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 150 |

overall look

inner look

rising

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts original overturn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° angle ensures to wash all side of the bottle, and can save the water.

filling

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ±2mm.

The filling valve material is SUS304

The filling system has liquid level automatic control.

Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck ,it start to fill.

Bottle is conveying by the wheel in the filling part.

The juice or other hot beverage can be backflow by return tank to control filling temperature.

capping

Screw capping machine is most precision part in the 3-1 machine, it has a big influence to the goods stability and defective rate. Our screw capping has following feature.

electrial system

about our company

We are the real factory in China which produces filling machine and package machine and other auxiliary equipment professionally.

We can provide beverage production line as below:

1. bottling minereal/pure water production line;

2. barrel mineral/ pure water production line

3. bottling carbonated beverage production line (like coca cola);

4. bottling juice production line;

5. canning beverage production line;

6. glass bottle beer production line;

7. milk/tea filling&package line;

8. oil filling&package line;

workshops

CERTIFICATE

JIAYUAN is always ready to fulfill your company’s needs according to your business goals.

(If you want to get your precise quotation,pls leave your capacity.thanks!)

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler