Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | CHINA, jiangsu |

| Brand Name: | JIAYUAN |

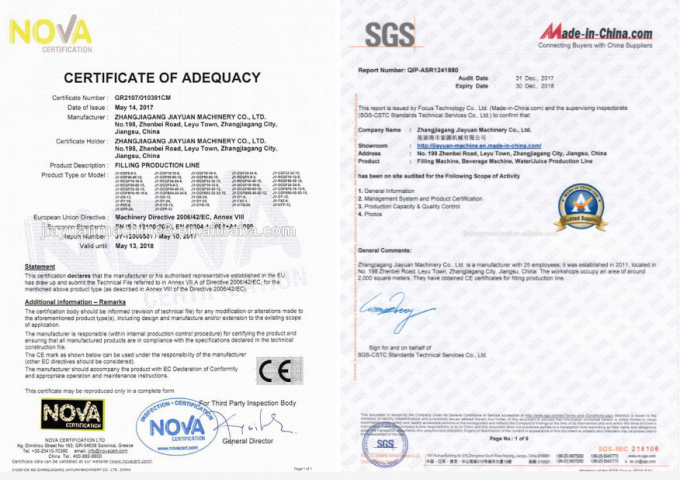

| Certification: | CE, SGS |

| Model Number: | CGF |

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD 4000-40000 per set |

| Packaging Details: | standard wooden cases |

| Delivery Time: | 35 working days |

| Supply Ability: | 100 set per year |

| Name: | Water Bottling Machine | Function: | Rising Filling Capping |

|---|---|---|---|

| Suibtable Bottle: | 330-2000ml PET Bottle | Filling Material: | Mineral Water, Pure Water |

| Capacity: | 2000-30000BPH | Control: | PLC+Touch Screen |

| Warranty: | 1 Year | ||

| High Light: | water bottling machine,water bottling equipment |

||

Characteristic of CGF series water bottling machine:

1. The suspending hottle-neckdamping design make the bottle stable during the high-speed moving conditions ,by changing a few parts it can meet the production of different types of bottles easily.

2. The new genernation of SS grabis adopted and the grabs have no contact ,with the area above the bottle's screw thread nozzles in the grad can guarantee the complete wash of the interior of the bottle.

3. The advanced graving filling technology used in this machine makes the filling quick ,steady and accurate.

4. Magnetic gorque is used for screw capping and the power of screw capping can be adjusted steplessly ,capping is realiable and do no harm to the caps.

5. Advanced technologies such as human-machine inter face touch-screen and PLC program control are adopted in this machine.

6. All parts that have direct contact witht he wafe are made of high quality SS ,the criticed dlectrical components are from famous interantional compies such asMitsubishi ,Omorn to the name a few.

7. Water bottling machine including of bottle rinsing filling capping 3 function in 1 machine.

Parameter

| Model | CGF12125 | CGF18186 | CGF24248 | CGF323210 | CGF404012 | CGF505012 | CGF606015 | CGF808020 |

| Number of washing, filling and capping heads | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 | 80-80-20 |

| Production capacity(600ml) (B/H) |

2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 | 25000-30000 | 35000-40000 |

| suitable bottle specification(mm) | φ=50-110=170 330-2250ml | |||||||

| Washing pressure(kg/cm 2 ) | 2-3 | |||||||

| Motor power(kw) | Main motor 2.2kw |

Main motor 2.2kw |

Main motor 3kw |

Main motor 5.5kw |

Main motor 7.5kw |

Main motor 11kw |

Main motor 15kw |

Main motor 19kw |

| Overall dimensions (mm) | 2400×1650 ×2500 |

2600×1920 ×2550 |

3100×2300 ×2800 |

3800×2800 ×2900 |

4600×2800 ×2900 |

5450×3300 ×2900 |

6500×4500 ×2900 |

76800×66400 ×2850 |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 150 |

overall look

inner look

rising

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts original overturn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° angle ensures to wash all side of the bottle, and can save the water.

filling

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ±2mm.

The filling valve material is SUS304

The filling system has liquid level automatic control.

Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck ,it start to fill.

Bottle is conveying by the wheel in the filling part.

The juice or other hot beverage can be backflow by return tank to control filling temperature.

capping

Screw capping machine is most precision part in the 3-1 machine, it has a big influence to the goods stability and defective rate. Our screw capping has following feature.

electrial system

about our company

We are the real factory in China which produces filling machine and package machine and other auxiliary equipment professionally.

We can provide beverage production line as below:

1. bottling minereal/pure water production line;

2. barrel mineral/ pure water production line

3. bottling carbonated beverage production line (like coca cola);

4. bottling juice production line;

5. canning beverage production line;

6. glass bottle beer production line;

7. milk/tea filling&package line;

8. oil filling&package line;

workshops

CERTIFICATE

CONTACT US

JIAYUAN is always ready to fulfill your company’s needs according to your business goals.

contact person: Alice chen

tel/whatsapp: 86 18306249355

email:jysales1@zjgjyjx.cn

(If you want to get your precise quotation,pls leave your capacity.thanks!)

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler