Zhangjiagang Jiayuan Machinery CO., LTD

Professional liquid beverage filling and packing machinery manufacturer

| Place of Origin: | China (mainland) |

| Brand Name: | JIAYUAN |

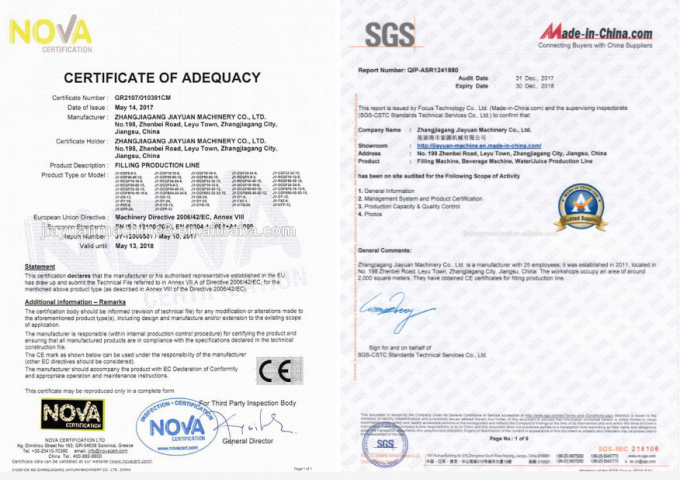

| Certification: | CE SGS |

| Model Number: | DCGF |

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | USD5000 per set |

| Packaging Details: | standard wooden cases |

| Delivery Time: | 35 working days |

| Supply Ability: | 100sets per year |

| Name: | Carbonated Drink Bottling Machine | Function: | Bottle Washing Filling Capping |

|---|---|---|---|

| Suitable Bottle: | PET Bottle | Bottle Volume: | 330-2000ml |

| Filling Material: | Carbonated Drink, Sparking Water, Soda Water ... | Capacity: | 2000-24000BPH |

| Material: | SUS304 | Warranty: | 1 Year |

| High Light: | Carbonated Soft Drink Filling Machine,CSD Filling Machine |

||

Carbonated beverage rising filling capping 3 in 1 machine

This production line is used for the production of fruit juice, vegetable protein drinks, function beverages, tea drinks and carbonated drinks. According to customers' requirements, we can design the

capacity of the line from 2000bph to 36000bph. The complete production line including fruit processing system/extraction treatment system, water treatment system, sugar melting system/soda mixing

system, homogenization &sterilization system, CIP system, bottle blowing system, bottle unscramble system, air deliver system, filling system, lamp check system, second sterilization system, labeling

machine, drying machine, coding machine, wrap shrinking machine, conveyor, boiler etc. Degree of automation can be configured according to customer requirements, provide process flow and

workshop layout design, full technical guidance.

Technical parameter

| odel |

DCGF 16-12-6 |

DCGF 18-18-6 |

DCGF 24-24-8 |

DCGF 32-32-10 |

DCGF 40-40-12 |

DCGF 50-50-15 |

| Washing No | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling No | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Production Capacity(500ml) | 3000BPH | 5000BPH | 8000BPH |

12000 BPH |

15000 BPH |

18000 BPH |

| Install Capacity(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall size | 2450×1800×2400 | 2650×1900×2400 | 2900×2100×2400 | 4100×2400×2400 | 4550×2650×2400 |

5450×3210×2400 |

Machine pictures

inner look

washing

filling

capping

details

3. The working process

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays juice to rinse bottle inwall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts equal pressure filling way. The filling valve opens and begins filling when it moves down and touches thebottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

about our company

Zhangjiagang JIAYUAN machinery manufactury Co.,Ltd is a manufacturer specialized in product design, equipment manufacturing, engineering, installation and technical research. Years of production experience, advanced manufacturing technology, excellent equipment quality, honest business philosophy, has won many well-known domestic and foreign customers recognition and support. With the efforts of all stuffs, products have been sold nationwide in 30 provinces, autonomous regions, and exported to the United States, Canada, Brazil, Peru, Russia, Mongolia, Kazakhstan, Uzbekistan, Malaysia, Myanmar, Indonesia, Sri Lanka, Pakistan, Nigeria, Algeria, Libya, Sudan, and other countries and regions.

our main production lines:

1. bottling minereal/pure water production line;

2. barrel mineral/ pure water production line

3. bottling carbonated beverage production line (like coca cola);

4. bottling juice production line;

5. canning beverage production line;

6. glass bottle beer production line;

7. milk/tea filling&package line;

8. oil filling&package line;

our two workshops

certificate

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

20000Bph Juice Bottle Filling Machine For HDPE Bottle , Water Filling Machine

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

Fully Automatic Juice Filling Machine 4000BPH For Round PET Bottle

Plastic Bottle Juice Filling Machine 6000BPH Ectric Cans Hot Filling Machine

3 In 1 Juice Bottling Equipment Stainless Steel / Filling Capping Machine

Mango Juice Monoblock Filling Equipment For 2000ml PET Bottle

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler